Most of our EPMA work is quantitative thin film analysis on Si substrates and there is really nothing that difficult about it, but it does help to run through the steps I think.

The biggest difference in the acquisition for thin film characterization is that one needs to acquire x-ray intensities at multiple electron beam energies for *both* the standards and unknowns.

Strictly speaking that isn't always necessary, but we find it provides the most accurate and reproducible results. In fact, because we will utilize all the beam energies when correcting for the matrix effects and the thin film sample geometry, we can often obtain a more "robust" analysis than using only one electron beam energy. Of course the usual caveats apply, especially surface contamination, native oxide and/or hydrocarbon layers, and insulating and/or beam sensitive films.

And don't even think that you can avoid correcting for geometry- unless you are, one, operating at extremely low overvoltages, i.e., shallow probe, two, using a very, very inclined sample to the beam, or three, your sample is thick enough that your electrons do not penetrate to the substrate, i.e., your sample is not really a thin film!

Basically we will be collecting x-ray intensities for our thin film elements, the substrate elements (to help with our thickness calculations) and also any contaminate elements such as oxygen. One time when we started seeing low totals in our thin films (yes, we also get useful totals in thin film analysis), we discovered that the samples were getting contaminated with Se from a previous deposition!

But in practice this method works very well, exactly because most of the beam does penetrate to the substrate depositing most of the energy in pure Si! Note therefore, as general a "rule of thumb", if you detect any substrate x-rays you *must* correct for a thin film geometry in your thin samples. But remember, because we are working with thin films, we are working with fewer atoms (50 nm = 500 atoms thick!), therefore you should treat thin film analyses as you would any trace element measurements with all necessary attention paid to the background characterization.

Ok, so the first step is to create a sample setup containing all the elements you need. Once you are tuned up and everything looks good (you did remember to run a careful wavescan to check for interfering off-peaks didn't you?), you will create three new sample setups based on the first and name them for the beam energies that they will have, for example 10 keV, 15 keV and 20 keV.

Also consider using multi-point backgrounds for highly variable thin film compositions where the background positions utilized for the background correction are "dynamic" and can change "on the fly" as discussed here:

http://probesoftware.com/smf/index.php?topic=56.msg218#msg218Of course the actual multiple voltages you utilize depends on the thickness of the thin film and the elements and x-ray lines you are using. Thinner films require lower voltages and lower energy x-ray lines sometimes. It is suggested that you model the film's likely chemistry and thickness and decide which voltages will produce the largest change in intensity with a change in electron beam energy.

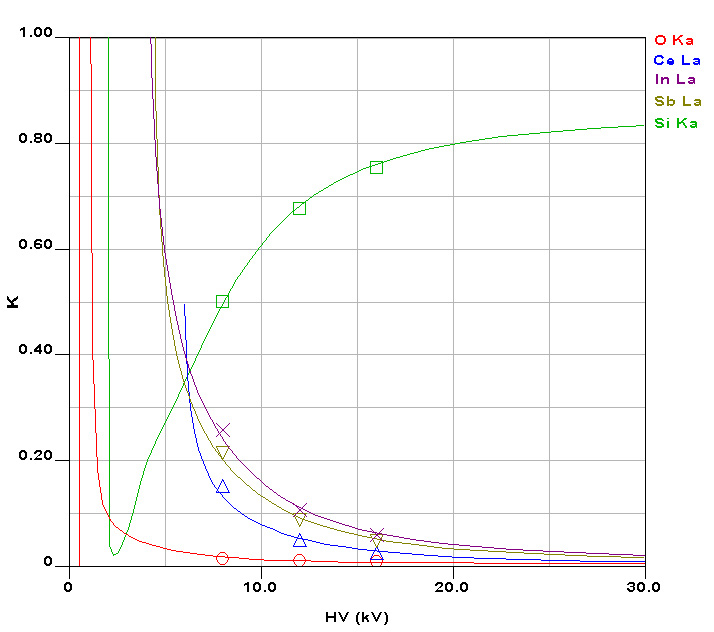

What we are after is a variation in the thin film element x-ray intensities as a function of beam energy as seen here:

The lines are the model (PAP) and the symbols are the EPMA measurements. From these measurements we can obtain both the composition and thickness of the film. Note that the signal from the substrate increases as the beam energy is increased.

More caveats, it is very difficult to measure a thin film containing an element that is also in the substrate. In the above case oxygen is present in the film, so we would not want to try measuring a thin film for oxygen on a substrate of, for example MgO. Or say, SiGe films on Si, though it *can* be done if the thickness is already known, see this paper for more details:

http://epmalab.uoregon.edu/pdfs/Determination%20of%20Ni-Si%20Ultra-thin%20Films,%20Phung,%20et.%20al.,%202008.pdfNext here's an example using La lines for mid-Z elements and this film is even thinner than the previous one. Also note the oxygen native oxide intensity increases as the voltage is lowered.

So now back to our acquisition.

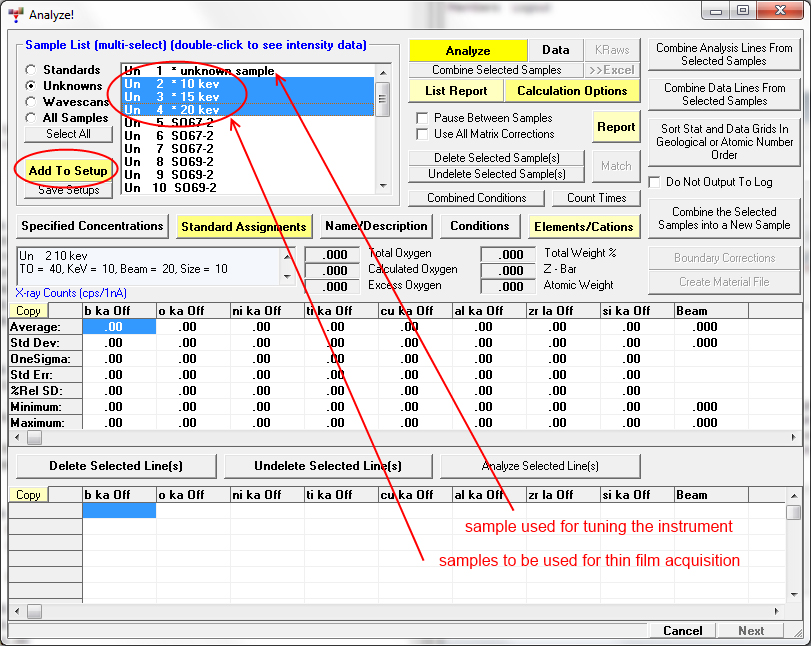

After creating and naming our sample setups for the beam energies we decided on, we then change the operating voltage on each sample (from the Analyze! window is best because then the instrument doesn't actually have to change beam energies) using the Conditions button.

Next we want to save these samples as sample setups that can be referenced for digitizing our samples. This is easily done by selecting all three samples and clicking the Add To Setup button in the Analyze! window as seen here:

Now we are ready to digitize our unknowns (assuming the standard positions have already been loaded into the Automate! window) using the Digitize window.

I generally digitize between 6 and 10 points per thin film because they are almost perfectly uniform when deposited using thermal evaporation, but films that are deposited by laser ablation can vary in both thickness *and* composition, so be careful. You do not want to average together points during the analysis that have different thickness and/or chemistry.

Once your points are digitized (and I usually check that I get all the little chips mounted on a 25 mm Al stub by using the StageMap window as seen here):

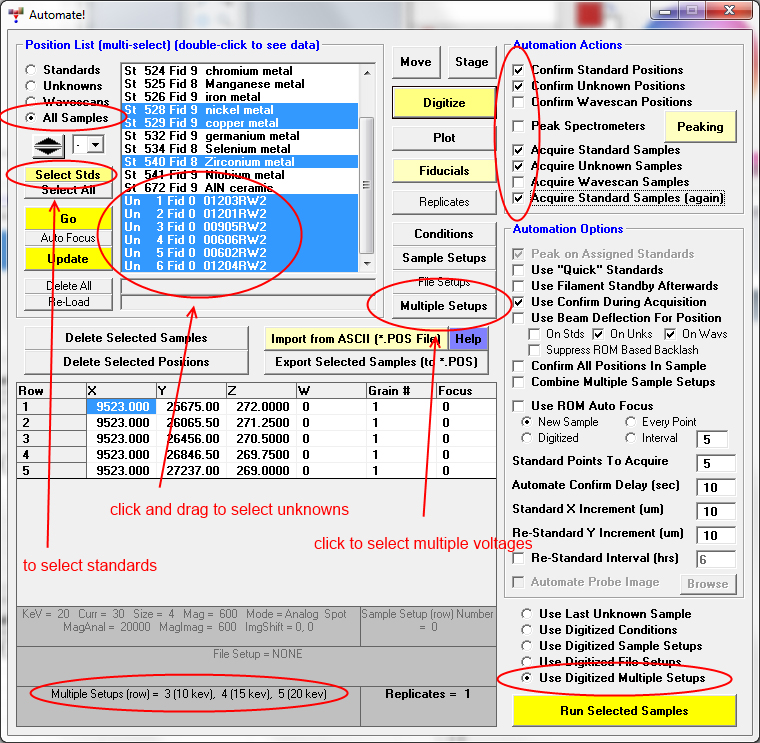

You can next select all your standards and unknown position samples in the Automate! window:

select the three sample setups for your three beam energies, and note the "automation basis" is now Use Digitized Multiple Setups.

And away you go!