Thank you Mike and Ben for your input. We are quite interested in this as we found that there was enough variation in the carbon coats on a sample vs the standard that the analytical totals were wacky, whereas the stoichiometry was perfect (plagioclase). Inputing different coat thickness values in PfE (from StrataGem k-ratios) saved the day. However, we noted that the thickness in StrataGem (which uses mass thickness) is a variable dependent upon density. So getting an accurate density would be rather useful.

Hi John et al.,

I ran into this same carbon coat density question yesterday on a metallurgical sample I am running for another university.

Basically it's a Ti-Nb couple and quite interesting because, for this system the diffusitivities (is that the correct word?) are different by around 5 orders of magnitude, so Nb diffuses readily into Ti, but Ti will not diffuse into Nb. Really weird.

Anyway, the sample is uncoated, but the standards are coated with our usual 20 nm of carbon. So when I went to do the quant I got this output:

Un 4 Ti-Nb boundary, Results in Elemental Weight Percents

ELEM: Ti Nb O

BGDS: EXP LIN EXP

TIME: 40.00 40.00 40.00

BEAM: 30.01 30.01 30.01

ELEM: Ti Nb O SUM

210 -.009 101.534 1.173 102.698

211 -.008 102.291 1.260 103.544

212 -.001 101.548 1.245 102.792

213 -.023 101.994 1.244 103.215

214 .026 101.660 1.221 102.908

215 .005 102.474 1.201 103.679

216 .063 102.108 1.287 103.458

217 .022 102.335 1.279 103.636

218 -.006 101.594 1.209 102.797

219 .043 101.464 1.317 102.824

220 .003 101.527 1.241 102.771

221 -.013 102.022 1.305 103.314

222 -.001 101.583 1.252 102.833

223 .030 101.848 1.171 103.049

224 .019 101.799 1.305 103.123

225 .035 102.506 1.309 103.849

This is using an 8 keV electron beam because they want the best spatial resolution they can get (we're doing another run tonight at 6 keV to try and further improve the spatial resolution and also to further reduce the SF effects).

Anyway, the above output clearly shows the need to specify the carbon coat for the standards and turn it off for the unknown. For the unknown this is easily done from the Calculation Options dialog by unchecking the "Use Unknown Conductive Coating" checkbox. For the standards one needs to use the Standard | Edit Standard Coating Parameters menu, but by default they are set to 200 nm of carbon at 2.1 gm/cm3.

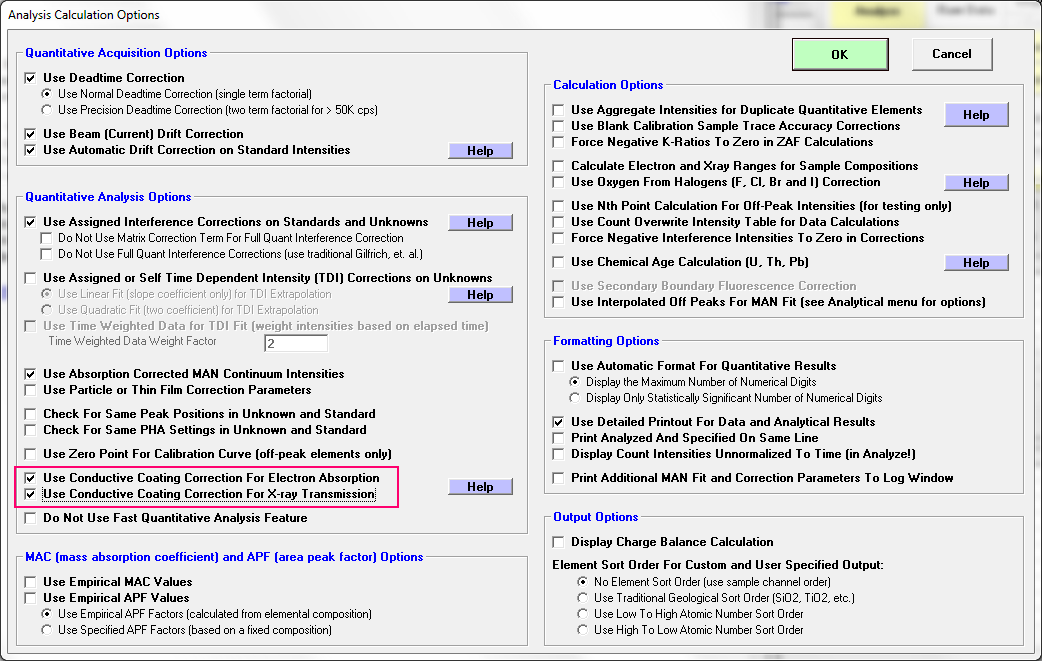

Then one has to go into the Analytical | Analysis Options dialog and explicitly turn on the conductive coating correction by checking these two checkboxes:

Once that is done we should be OK (or should we?), and we now obtain this analysis:

Un 4 Ti-Nb boundary, Results in Elemental Weight Percents

ELEM: Ti Nb O

BGDS: EXP LIN EXP

TIME: 40.00 40.00 40.00

BEAM: 30.01 30.01 30.01

ELEM: Ti Nb O SUM

210 -.008 95.301 1.024 96.316

211 -.007 96.010 1.099 97.102

212 -.001 95.313 1.086 96.398

213 -.021 95.731 1.085 96.795

214 .024 95.418 1.065 96.508

215 .004 96.183 1.047 97.234

216 .057 95.838 1.122 97.017

217 .020 96.051 1.116 97.187

218 -.005 95.357 1.054 96.406

219 .040 95.232 1.149 96.421

220 .003 95.293 1.083 96.379

221 -.011 95.756 1.139 96.883

222 -.001 95.345 1.092 96.436

223 .028 95.596 1.021 96.645

224 .017 95.547 1.138 96.703

225 .032 96.210 1.142 97.384

So now our analysis is low! Of course these coating effects are significantly amplified when running at low voltage (or low overvoltage), but we're pretty sure that the coating on our standards is close to 20 nm based on the color on polished brass as discussed here:

http://probesoftware.com/smf/index.php?topic=921.msg7063#msg7063So then there's the density question and the consensus above seems to be that the evaporated deposited coatings are often less dense than their "accepted" values. So I changed the carbon density from 2.1 to 1.4 and voila:

Un 4 Ti-Nb boundary, Results in Elemental Weight Percents

ELEM: Ti Nb O

BGDS: EXP LIN EXP

TIME: 40.00 40.00 40.00

BEAM: 30.01 30.01 30.01

ELEM: Ti Nb O SUM

210 -.008 97.376 1.072 98.439

211 -.007 98.101 1.151 99.245

212 -.001 97.389 1.137 98.524

213 -.022 97.816 1.136 98.931

214 .025 97.496 1.116 98.637

215 .004 98.277 1.096 99.378

216 .059 97.925 1.175 99.159

217 .021 98.143 1.168 99.332

218 -.005 97.433 1.104 98.532

219 .041 97.307 1.203 98.550

220 .003 97.368 1.134 98.505

221 -.012 97.842 1.192 99.022

222 -.001 97.422 1.143 98.564

223 .029 97.677 1.069 98.775

224 .018 97.629 1.192 98.838

225 .033 98.306 1.195 99.534

You gotta admit, that's pretty impressive...