Update on ours: I found a bad detector window and having checked all the column separation windows, ended up replacing one thick film window that looked a bit blown (couldn't really see any holes though). Surprisingly, the thin film windows all looked pristine, so I'm not convinced any of the column windows were actually bad.

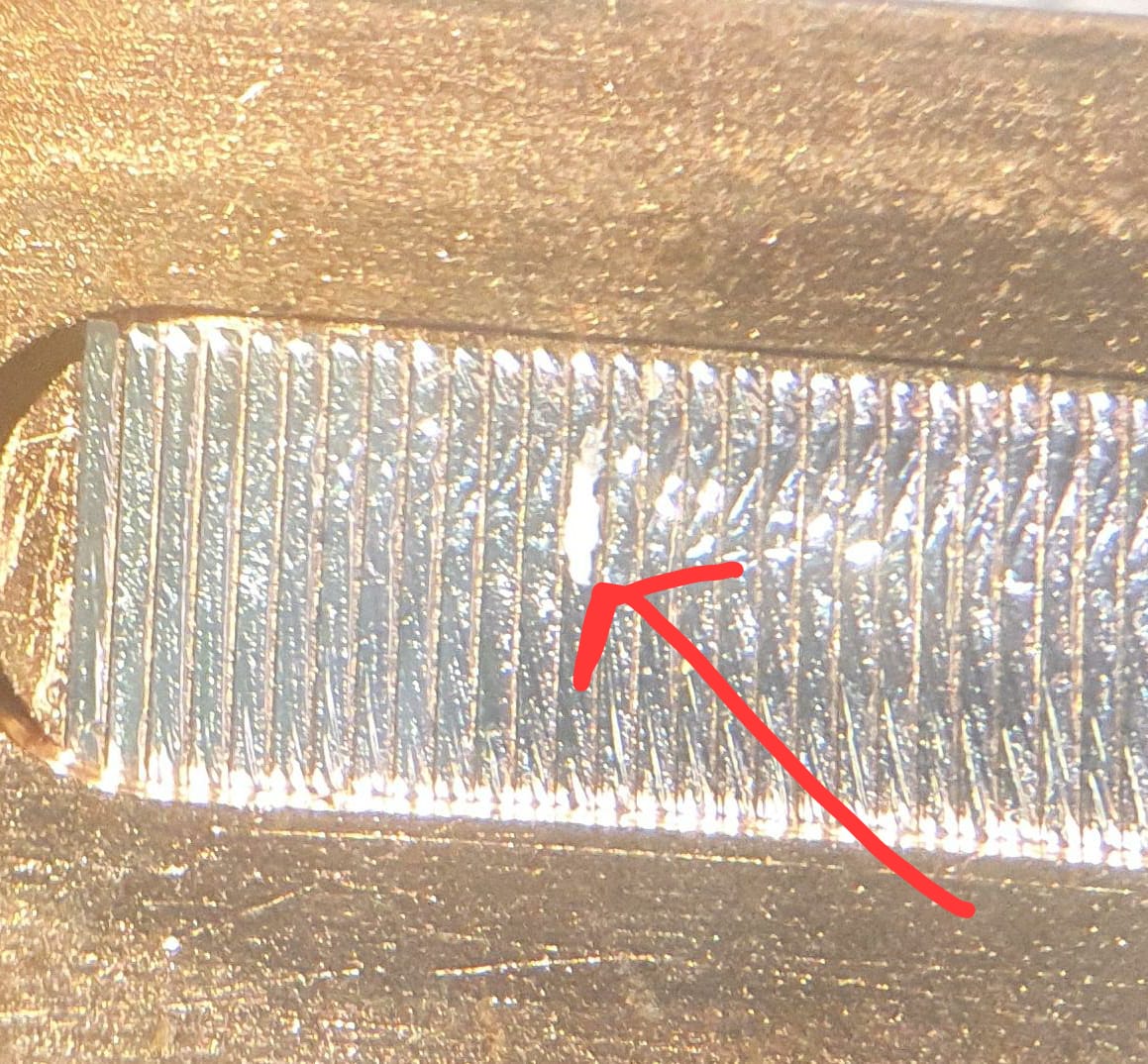

I stuck the detector window under a microscope and took a few pictures.

For scale, the window is approx 1 cm across the short dimension, the hole up to maybe 1 mm in length.

Typically, this window was from SP5 and was a pig to get out as we have the liquid nitrogen anti-contamination dewar fitted, severely reducing access.

Top tip: fill all the gaps in the table underneath with tin foil or blue roll! When the circlip holding the detector pops off, or when you drop it on refitting, it will fall in to the tin foil and not down in to the bottom of the instrument amongst the pipes and cabling. Saved my bacon, that did!

I'm waiting a while for the vacuum to recover before I restart the ion pump, but fingers crossed this has sorted out the ion pump tripping out!