I ran some additional high precision (15 keV, 50 nA, 10 um, 100 seconds per point, 400 points) scans on both LLIF and LPET crystals. Here are the LLIF scans for Va Ka on both TiO2 and TiC normalized to the Ti Kb:

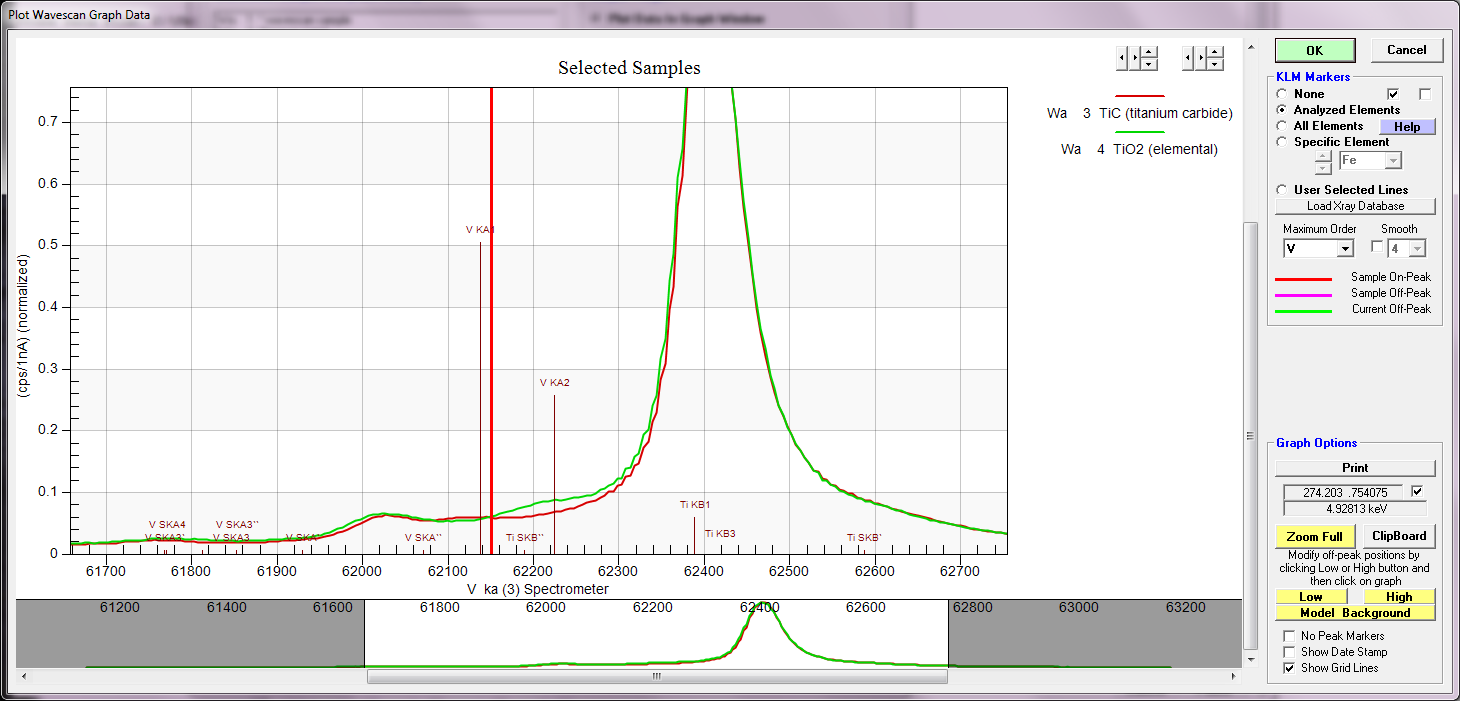

and here for LPET:

So I don't understand completely what is going on but here's a few observations regrading these interferences/blank corrections when analyzing TiC using TiO2 for both the primary standard and for the interference standard for the quantitative interference correction... it's amazing it works as well as it does!

First here we have no interference or blank corrections using only LIF crystals on TiC:

ELEM: Ti Ti-D V V-D Sr Fe Cr Mn C SUM

XRAY: (ka) (ka) (ka) (ka) () () () () ()

162 78.759 --- .725 --- .000 .000 .000 .000 20.000 99.484

163 78.540 --- .720 --- .000 .000 .000 .000 20.000 99.260

164 78.196 --- .723 --- .000 .000 .000 .000 20.000 98.919

165 78.437 --- .737 --- .000 .000 .000 .000 20.000 99.174

166 78.628 --- .720 --- .000 .000 .000 .000 20.000 99.348

167 78.765 --- .701 --- .000 .000 .000 .000 20.000 99.466

AVER: 78.554 --- .721 --- .000 .000 .000 .000 20.000 99.275

SDEV: .216 --- .012 --- .000 .000 .000 .000 .000 .211

SERR: .088 --- .005 --- .000 .000 .000 .000 .000

%RSD: .28 --- 1.63 --- .00 .00 .00 .00 .00

STDS: 922 --- 923 --- --- --- --- --- ---

If we turn on the interference correction using TiO2 as our interference standard only we get this:

ELEM: Ti Ti V V Sr Fe Cr Mn C

TYPE: ANAL ANAL ANAL ANAL SPEC SPEC SPEC SPEC SPEC

BGDS: LIN EXP LIN EXP

TIME: 60.00 --- 60.00 --- --- --- --- --- ---

BEAM: 30.03 --- 30.03 --- --- --- --- --- ---

ELEM: Ti Ti-D V V-D Sr Fe Cr Mn C SUM

XRAY: (ka) (ka) (ka) (ka) () () () () ()

162 78.797 --- .008 --- .000 .000 .000 .000 20.000 98.805

163 78.577 --- .005 --- .000 .000 .000 .000 20.000 98.583

164 78.233 --- .011 --- .000 .000 .000 .000 20.000 98.245

165 78.474 --- .024 --- .000 .000 .000 .000 20.000 98.498

166 78.665 --- .004 --- .000 .000 .000 .000 20.000 98.670

167 78.803 --- -.016 --- .000 .000 .000 .000 20.000 98.787

AVER: 78.592 --- .006 --- .000 .000 .000 .000 20.000 98.598

SDEV: .216 --- .013 --- .000 .000 .000 .000 .000 .209

SERR: .088 --- .005 --- .000 .000 .000 .000 .000

%RSD: .28 --- 211.68 --- .00 .00 .00 .00 .00

STDS: 922 --- 923 --- --- --- --- --- ---

The vanadium is within a standard deviation. One could also simply apply the TiC standard (acquired as an unknown) as a blank without an interference correction as seen here:

ELEM: Ti Ti-D V V-D Sr Fe Cr Mn C SUM

XRAY: (ka) (ka) (ka) (ka) () () () () ()

174 78.239 --- .012 --- .000 .000 .000 .000 20.000 98.252

175 78.794 --- .003 --- .000 .000 .000 .000 20.000 98.796

176 78.508 --- .017 --- .000 .000 .000 .000 20.000 98.525

177 78.669 --- .013 --- .000 .000 .000 .000 20.000 98.682

178 78.899 --- -.005 --- .000 .000 .000 .000 20.000 98.895

AVER: 78.622 --- .008 --- .000 .000 .000 .000 20.000 98.630

SDEV: .259 --- .009 --- .000 .000 .000 .000 .000 .252

SERR: .116 --- .004 --- .000 .000 .000 .000 .000

%RSD: .33 --- 109.73 --- .00 .00 .00 .00 .00

PUBL: 80.000 n.a. n.a. n.a. n.a. n.a. n.a. n.a. 20.000 100.000

%VAR: -1.72 --- --- --- --- --- --- --- .00

DIFF: -1.378 --- --- --- --- --- --- --- .000

STDS: 922 --- 923 --- --- --- --- --- ---

Also within a standard deviation. In this case either the interference correction or the blank correction appear to work equally well.

Now let's do a "failure mode" analysis on PET crystals! Again, not recommended, but an interesting failure mode test. Here is the TiC without an interference correction or a blank correction:

ELEM: Ti-D Ti V-D V Sr Fe Cr Mn C SUM

XRAY: (ka) (ka) (ka) (ka) () () () () ()

162 --- 80.029 --- 3.952 .000 .000 .000 .000 20.000 103.980

163 --- 80.008 --- 3.968 .000 .000 .000 .000 20.000 103.977

164 --- 79.856 --- 3.965 .000 .000 .000 .000 20.000 103.821

165 --- 79.888 --- 3.966 .000 .000 .000 .000 20.000 103.854

166 --- 79.687 --- 3.947 .000 .000 .000 .000 20.000 103.634

167 --- 79.986 --- 4.003 .000 .000 .000 .000 20.000 103.989

AVER: --- 79.909 --- 3.967 .000 .000 .000 .000 20.000 103.876

SDEV: --- .129 --- .020 .000 .000 .000 .000 .000 .139

SERR: --- .053 --- .008 .000 .000 .000 .000 .000

%RSD: --- .16 --- .50 .00 .00 .00 .00 .00

STDS: --- 922 --- 923 --- --- --- --- ---

That's a big interference! Now let's turn on the interference correction using TiO2 as the interference standard:

ELEM: Ti-D Ti V-D V Sr Fe Cr Mn C SUM

XRAY: (ka) (ka) (ka) (ka) () () () () ()

162 --- 80.229 --- -.030 .000 .000 .000 .000 20.000 100.199

163 --- 80.209 --- -.014 .000 .000 .000 .000 20.000 100.195

164 --- 80.056 --- -.012 .000 .000 .000 .000 20.000 100.044

165 --- 80.088 --- -.014 .000 .000 .000 .000 20.000 100.075

166 --- 79.887 --- -.025 .000 .000 .000 .000 20.000 99.862

167 --- 80.187 --- .014 .000 .000 .000 .000 20.000 100.202

AVER: --- 80.110 --- -.014 .000 .000 .000 .000 20.000 100.096

SDEV: --- .129 --- .015 .000 .000 .000 .000 .000 .134

SERR: --- .053 --- .006 .000 .000 .000 .000 .000

%RSD: --- .16 --- -114.32 .00 .00 .00 .00 .00

STDS: --- 922 --- 923 --- --- --- --- ---

A bit of an over correction, but still within a standard deviation! Now just the blank correction using TiC as the blank:

ELEM: Ti-D Ti V-D V Sr Fe Cr Mn C SUM

XRAY: (ka) (ka) (ka) (ka) () () () () ()

174 --- 80.149 --- .041 .000 .000 .000 .000 20.000 100.191

175 --- 79.987 --- .036 .000 .000 .000 .000 20.000 100.023

176 --- 80.062 --- .026 .000 .000 .000 .000 20.000 100.088

177 --- 80.420 --- .040 .000 .000 .000 .000 20.000 100.461

178 --- 80.240 --- .047 .000 .000 .000 .000 20.000 100.287

AVER: --- 80.172 --- .038 .000 .000 .000 .000 20.000 100.210

SDEV: --- .168 --- .008 .000 .000 .000 .000 .000 .172

SERR: --- .075 --- .003 .000 .000 .000 .000 .000

%RSD: --- .21 --- 20.47 .00 .00 .00 .00 .00

PUBL: n.a. 80.000 n.a. n.a. n.a. n.a. n.a. n.a. 20.000 100.000

%VAR: --- .21 --- --- --- --- --- --- .00

DIFF: --- .172 --- --- --- --- --- --- .000

STDS: --- 922 --- 923 --- --- --- --- ---

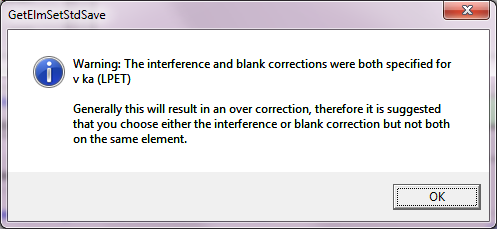

Not as good as the interference correction. Let's try turning both on! First the software warns us with this message:

and here are the results with both corrections turned on:

ELEM: Ti-D Ti V-D V Sr Fe Cr Mn C SUM

XRAY: (ka) (ka) (ka) (ka) () () () () ()

174 --- 80.169 --- -.341 .000 .000 .000 .000 20.000 99.829

175 --- 80.007 --- -.338 .000 .000 .000 .000 20.000 99.669

176 --- 80.082 --- -.353 .000 .000 .000 .000 20.000 99.729

177 --- 80.441 --- -.358 .000 .000 .000 .000 20.000 100.083

178 --- 80.261 --- -.343 .000 .000 .000 .000 20.000 99.918

AVER: --- 80.192 --- -.346 .000 .000 .000 .000 20.000 99.846

SDEV: --- .169 --- .009 .000 .000 .000 .000 .000 .163

SERR: --- .075 --- .004 .000 .000 .000 .000 .000

%RSD: --- .21 --- -2.51 .00 .00 .00 .00 .00

PUBL: n.a. 80.000 n.a. n.a. n.a. n.a. n.a. n.a. 20.000 100.000

%VAR: --- .24 --- --- --- --- --- --- .00

DIFF: --- .192 --- --- --- --- --- --- .000

STDS: --- 922 --- 923 --- --- --- --- ---

Indeed an over correction!

I'm still trying to understand all of these implications, but it seems to me that the interference correction, because it is multiplicative, is best applied to artifacts that scale with concentration, while the blank correction, because it is subtractive, is best applied to artifacts that are more constant, for example continuum artifacts.

Just to finish up here is the LiF analysis with both the interference and blank corrections turned on:

ELEM: Ti Ti V V Sr Fe Cr Mn C

TYPE: ANAL ANAL ANAL ANAL SPEC SPEC SPEC SPEC SPEC

BGDS: LIN EXP LIN EXP

TIME: 60.00 --- 60.00 --- --- --- --- --- ---

BEAM: 30.03 --- 30.03 --- --- --- --- --- ---

ELEM: Ti Ti-D V V-D Sr Fe Cr Mn C SUM

XRAY: (ka) (ka) (ka) (ka) () () () () ()

174 78.239 --- .014 --- .000 .000 .000 .000 20.000 98.253

175 78.794 --- -.001 --- .000 .000 .000 .000 20.000 98.793

176 78.508 --- .016 --- .000 .000 .000 .000 20.000 98.524

177 78.669 --- .010 --- .000 .000 .000 .000 20.000 98.679

178 78.900 --- -.010 --- .000 .000 .000 .000 20.000 98.890

AVER: 78.622 --- .006 --- .000 .000 .000 .000 20.000 98.628

SDEV: .259 --- .011 --- .000 .000 .000 .000 .000 .250

SERR: .116 --- .005 --- .000 .000 .000 .000 .000

%RSD: .33 --- 190.48 --- .00 .00 .00 .00 .00

PUBL: 80.000 n.a. n.a. n.a. n.a. n.a. n.a. n.a. 20.000 100.000

%VAR: -1.72 --- --- --- --- --- --- --- .00

DIFF: -1.378 --- --- --- --- --- --- --- .000

STDS: 922 --- 923 --- --- --- --- --- ---

STKF: .5552 --- .6328 --- --- --- --- --- ---

STCT: 45.56 --- 262.26 --- --- --- --- --- ---

UNKF: .7527 --- .0001 --- --- --- --- --- ---

UNCT: 61.78 --- .02 --- --- --- --- --- ---

UNBG: .20 --- .63 --- --- --- --- --- ---

ZCOR: 1.0445 --- 1.0666 --- --- --- --- --- ---

KRAW: 1.3558 --- .0001 --- --- --- --- --- ---

PKBG: 309.56 --- 1.04 --- --- --- --- --- ---

INT%: ---- --- -98.39 --- --- --- --- --- ---

BLNK#: ---- --- 3 --- --- --- --- --- ---

BLNKL: ---- --- .000000 --- --- --- --- --- ---

BLNKV: ---- --- .006107 --- --- --- --- --- ---

This does not appear to result in an over correction, I suspect because the blank correction level is only 60 PPM.