Hi Anne,

Another method that might work for you is to simply mount your double polished glass samples on a Si wafer, with only a tiny drop of isopropyl alcohol acting as the "adhesive". I'm not sure quite what is going on as the alcohol capillaries around the sample and dries, but I'm guessing that the alcohol dissolves trace amounts of oils and other hydrocarbons already present, and as it "wicks" around the sample and dries, it makes a surprisingly strong bond. The sample can still removed using a needle gently, but it stays in place for normal handling and EPMA work, I do know from experience. Whether it will stay put for LA-ICPMS is another question, but I'll bet it will. Worth a test I think.

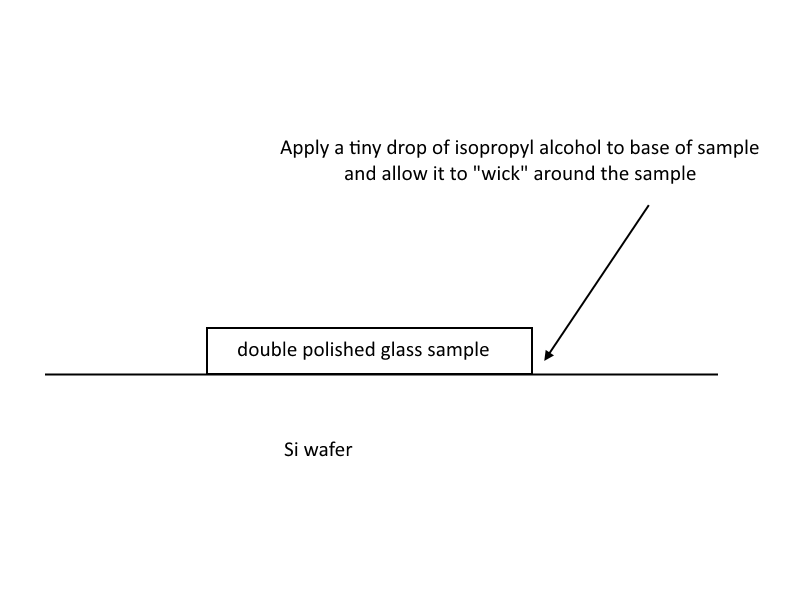

Basically one places the sample on a Si wafer (which is very flat of course), and then using a needle, one applies the smallest possible drop of isopropyl alcohol to the bottom edge of the glass sample and the surface of the Si wafer as seen here:

Also if the tiny drop of alcohol is placed right in the corner of the sample, it only wicks around the bottom and sides of the sample, and won't ooze over the top edge of the sample, so your sample surface stays uncontaminated, and of course flat and level since the dried residue has essentially no thickness. We've often used this method for mounting micro samples in the lab of all shapes and I think it should work for your flat geological samples as well.

We have 5 x 5 mm Si wafers in the lab and one can also get 5 x 7 mm Si wafers here:

https://www.2spi.com/item/z4136sc/silicon-wafers/Another idea that I might look into is getting 25 mm (1") round Si wafers, so they can mounted right in a standard sample holder without having to glue the Si wafer to an Al puck for mounting in the instrument's sample holder. Here's a company that says they can provide 25mm Si wafers. I'm going to check to see how expensive they are, but on the other hand if we're using the above isopropyl mounting method, the wafers will be re-usable at least.

http://www.addisonengineering.com/silicon-wafers.htmljohn