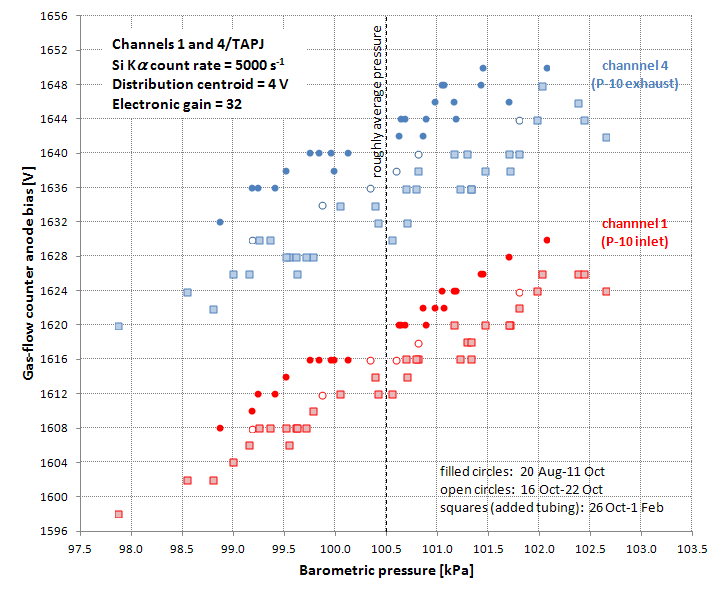

I’ve continued to add to my plot of GFPC anode bias versus atmospheric pressure over the past few months. It appears that the addition of 22 feet of tubing to the channel 4 exhaust had little or no effect, and this is a little puzzling. I expected the added tubing to at least reduce the amount of scatter present in the measurements on channel 4, but the magnitude of the scatter appears unchanged.

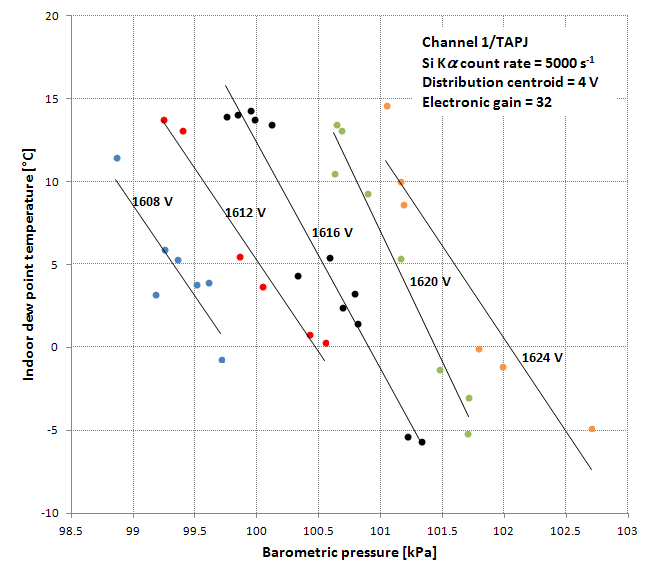

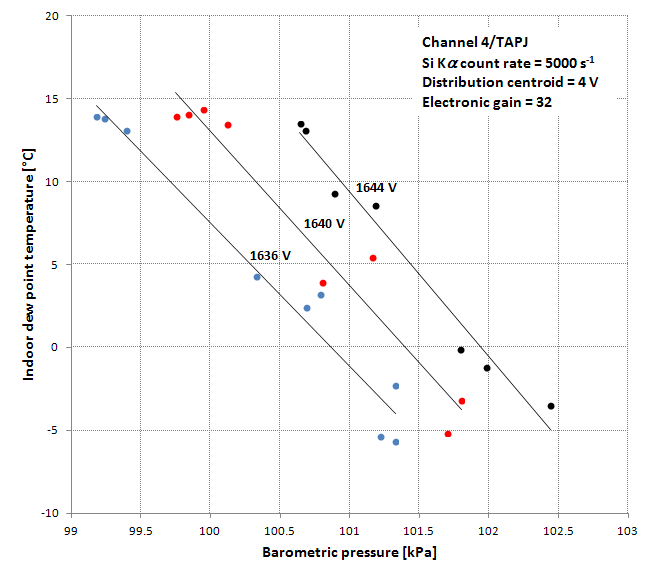

Clearly at least one other independent variable (in addition to atmospheric pressure) is important in order to account for scatter in the plot. In the following plots, I’ve contoured indoor dew point temperature versus atmospheric pressure for anode bias in 4 V increments. Although the plots would benefit from some more measurements, it seems clear that water content of the atmosphere affects the anode bias required to keep the distribution centered at 4 V (while maintaining count rate at 5000 s

-1), even with the added tubing. So I’m sticking to my claim that air is actually mixing with P-10 in the gas-flow counters. On the plot above, as dew point decreases (to as low as ~-5°C in the past month) the anode bias for given atmospheric pressure also decreases. (In the summer, dew point temperature ranges as high as ~+15°C.)

I’ll keep adding to these plots at least through next summer to see if my results from late last summer are reproducible. By the way, I’m keeping track of dew point with the Lascar EL-USB-RT thermometer/hygrometer, which displays temperature and dew point in real time and also periodically dumps data to a file. It can be gotten at Amazon for about $60 U.S.