What do you mean by a EPMA scan. - are you quantifying using wavescans.

Normally you peak up on Aluminium metal standard, measure pk counts, and bkg counts. (Wavescan may be useful to identify bkg positions on standard and unknown). Then measure pk counts and bkg counts on unknown sample (AlCo alloy).

Things to check

Is you Aluminum metal standard heavily oxidised?

Also their may be a matrix correction problem (once you've done all the measures correctly) - do you have AlCo alloy standards.

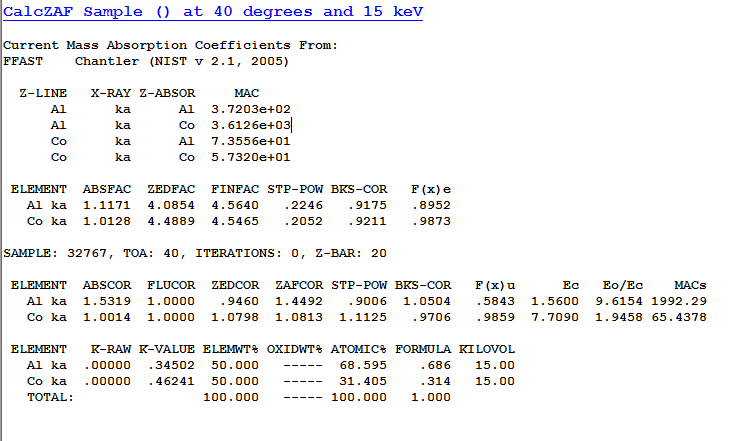

Have a look at the ZAF values - are the matrix corrections large. If the matrix corrections are large you could try different phi-rho-z model or MAC.

Here's an example of matrix correction using calczaf for alloy with 50% wt.% Al and 50% Co

You can see Al has a absorption correction of 1.5 and Z correction of 1.4

Ben