Note that if you have Probe for EPMA you can perform a boundary fluorescence correction directly on your unknown data from the Analyze! Window:

https://probesoftware.com/smf/index.php?topic=1545.0

Note that the SF boundary correction does not yet incorporate a Bragg defocus calibration, so at the moment it is a worse case scenario correction. Which depends on the orientation of the boundary relative to the Bragg crystal on the spectrometer being utilized.

But I believe a Bragg defocus calibration is currently being developed…

Until this Bragg defocus correction is implemented and one wants to correct for secondary boundary fluorescence (as opposed to FIBing out the sample and mounting the individual grains to avoid fluorescence from nearby phases), you should orient your sample in the stage so that the spectrometer making the trace element is aligned with the boundary. That is the phase boundary you are making measurements adjacent to, should point towards the spectrometer making the trace measurement. Then as one moves the stage away from the adjacent boundary, there is little to no Bragg defocus effects.

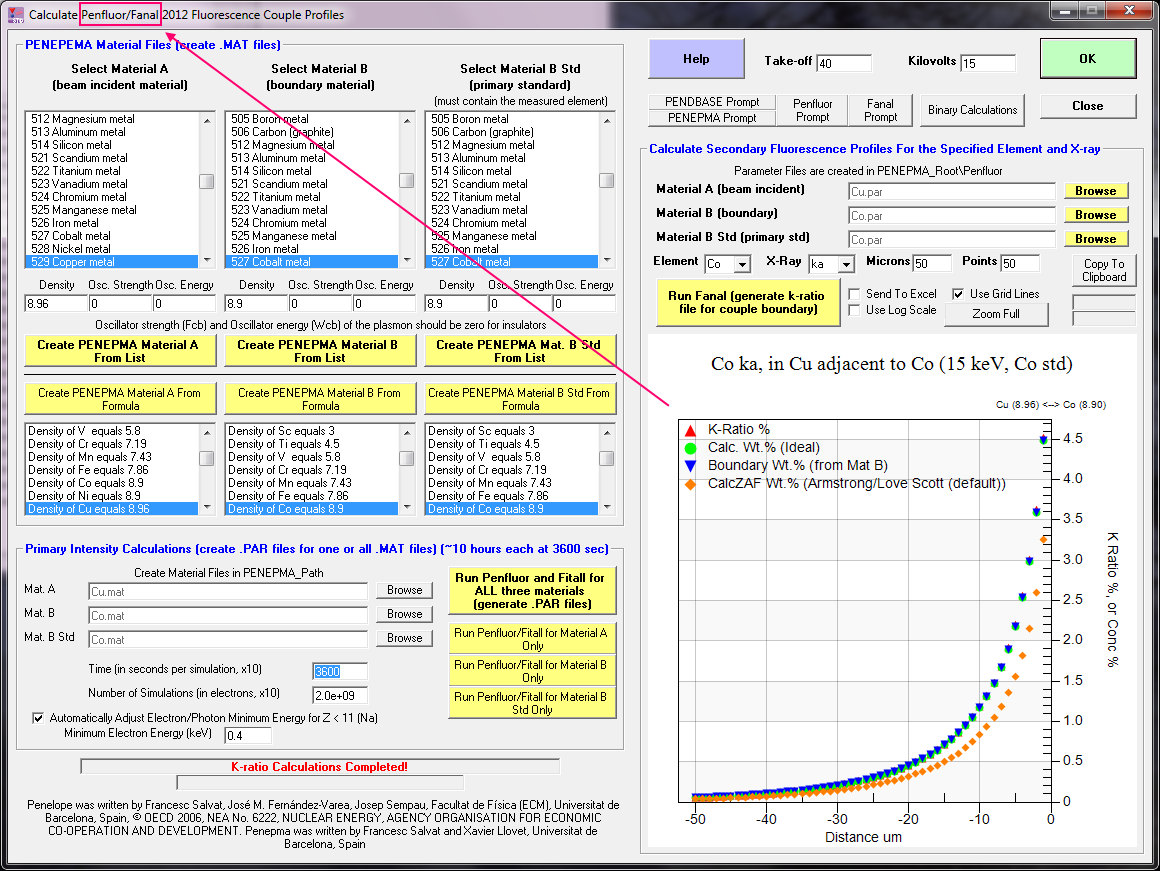

And because the Bragg defocus effects are minimized, the boundary fluorescence model calculated from PENFLUOR/FANAL will not over correct the k-ratios.

Of course the opposite approach can also be attempted whereby one orients their specimen in the sample stage so that the adjacent boundary points directly *away* (at 90 degrees) from the spectrometer making the trace measurement. And then one limits their trace measurements to points being at least 50 or 100 um away from the adjacent boundary. Then one might hope that the WDS Bragg defocus reduces the detection of the boundary fluorescence emissions and no boundary fluorescence correction is necessary.

Of course with EDS there are no Bragg defocus effects, so the model from PENFLUOR/FANAL should apply as is for elements measured by EDS.

To post in-line images, login and click on the Gallery link at the top

To post in-line images, login and click on the Gallery link at the top Recent Posts

Recent Posts