Warning, this post might be painful to read.

I recently got some large (1.5") metallurgical Fe diffusion samples from a colleague to characterize the diffusion profiles. Unfortunately the samples are quite magnetic and even using the above mentioned demagnetizer did not help. So depending exactly where on the sample I am, the electron beam is significantly deflected away from the WDS x-ray focus location.

Now normally when we have run into samples that cannot be demagnetized, we simply run the analyses using EDS with full standards in Probe for EPMA as this allows us to perform spectral interference corrections, but unfortunately these analyses require characterization of carbon. And trace carbon by EDS in an Fe, V, Nb alloy is just not going to cut it in my opinion (though I'd be interested to learn otherwise).

Now carbon characterization in a microprobe is hard enough (need to have an uncoated sample and turn off the coating correction the unknowns but leave it on for the standards, use the TDI correction, deal with spectral interferences, etc., etc.), but when one adds severe beam deflection from magnetic samples into the mix, it really is a pain.

For example, when comparing the optical image with the electron image, in one analysis location I'm seeing 49 um of deflection in X and 12 um in Y. In other areas the deflection is just as large but different! If I simply go ahead and run normal WDS analyses I get ~90% totals because of Bragg defocussing.

So I'm sitting there thinking how the heck am I going to do this? I could have used the digitized image feature that allows one to acquire a BSE image and then digitize the points right on the image. And since the image would be deflected by the magnetic field just like the spot beam, the beam deflection should all null out. But for analysis areas larger then the 20 um or so, one is still going to have Bragg defocus issues, and I can't use EDS because they want trace carbon.

So then I wondered about image shift, because the deflection from the magnetic sample is roughly constant over a mm or so. But image shift doesn't really work in spot mode-

or does it?So I switched to scan mode, and looking at the optical image, I adjusted the image shift until the center of the electron image coincided with the optical image. I then manually switched the beam mode to spot, and low and behold, the beam spot showed up and was deflected, even though the image shift controls are now non responsive (as one would expect)! At least this is the case on my Cameca SX100.

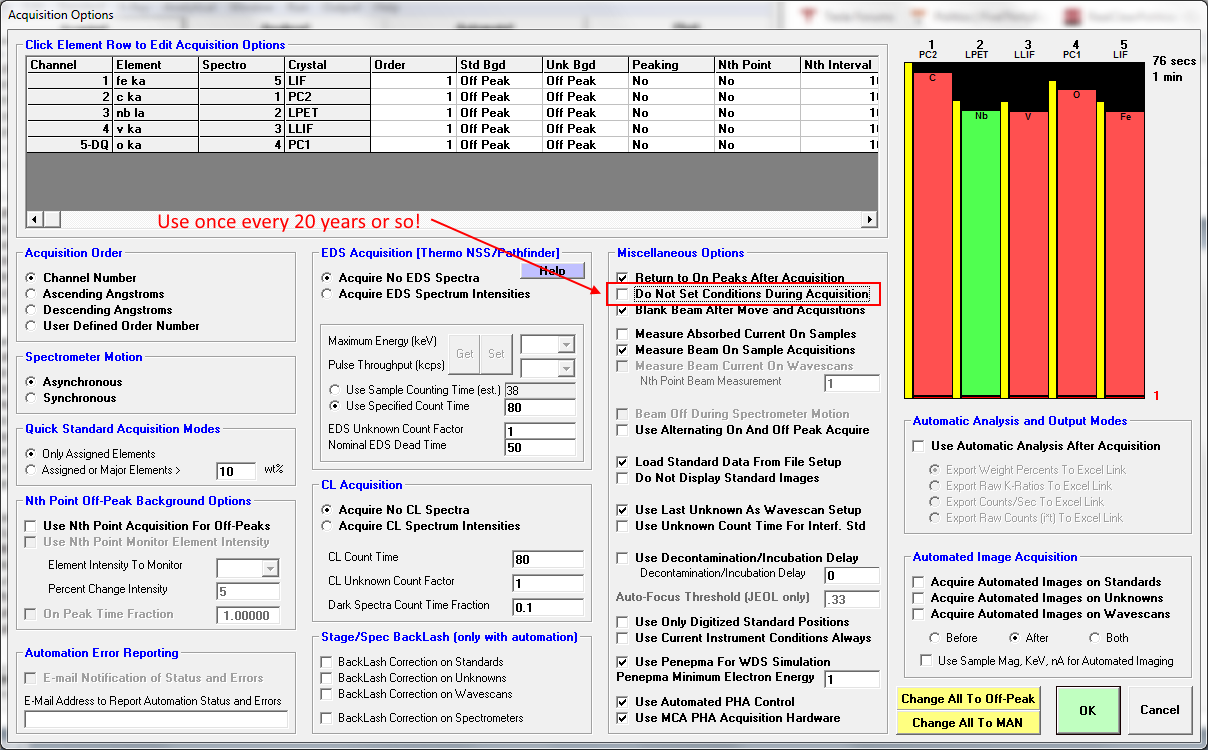

So, then what I did was to utilize a checkbox in PFE that I don't think I've ever used before, but in this situation it is essential, and that is this one here that is normally checked, but I simply unchecked it:

Now the deal is to be sure that the beam and column conditions are exactly as you want them otherwise, and then the software acquires the data with the deflected spot mode beam that hopefully is compensating for the beam deflection caused by the magnetic sample.

And after this, I calculated the results and instead of 90% totals we're doing much better:

n 7 1AV, 3

Un 7 1AV, 3

TakeOff = 40.0 KiloVolt = 15.0 Beam Current = 30.0 Beam Size = 0

(Magnification (analytical) = 40000), Beam Mode = Analog Spot

(Magnification (default) = 2245, Magnification (imaging) = 800)

Image Shift (X,Y): .00, .00

Number of Data Lines: 48 Number of 'Good' Data Lines: 48

First/Last Date-Time: 10/08/2018 05:27:47 PM to 10/08/2018 07:22:20 PM

WARNING- Using Exponential Off-Peak correction for c ka

WARNING- Using Exponential Off-Peak correction for v ka

WARNING- Using Exponential Off-Peak correction for o ka

WARNING- Using Time Dependent Intensity (TDI) Element Correction

WARNING- Using Blank Trace Correction

WARNING- Quantitation is Disabled For o ka, Spectro 4

Average Total Oxygen: .000 Average Total Weight%: 98.565

Average Calculated Oxygen: .000 Average Atomic Number: 24.215

Average Excess Oxygen: .000 Average Atomic Weight: 51.558

Average ZAF Iteration: 2.96 Average Quant Iterate: 3.98

No Sample Coating and/or No Sample Coating Correction

Un 7 1AV, 3, Results in Elemental Weight Percents

ELEM: Fe C Nb V O

BGDS: LIN EXP LIN EXP EXP

TIME: 40.00 40.00 40.00 40.00 ---

BEAM: 30.10 30.10 30.10 30.10 ---

ELEM: Fe C Nb V O-D SUM

327 .009 -.019 .000 100.017 --- 100.006

328 .020 1.103 .000 98.865 --- 99.989

329 .033 .053 -.002 99.280 --- 99.364

330 .030 .141 -.006 98.915 --- 99.081

331 .017 .113 .008 98.143 --- 98.281

332 .042 -.065 -.011 98.559 --- 98.525

333 .034 -.045 .016 98.617 --- 98.622

334 .035 .042 .002 98.318 --- 98.398

335 .467 4.042 -.011 95.773 --- 100.271

336 16.404 .070 -.021 82.303 --- 98.756

337 36.791 .044 .002 62.380 --- 99.217

338 42.883 .098 .004 55.452 --- 98.437

339 46.199 .123 -.013 51.821 --- 98.130

340 48.929 .131 -.004 49.326 --- 98.382

341 38.853 18.902 -.013 39.861 --- 97.603

342 51.870 .570 .001 45.361 --- 97.803

343 54.801 .174 -.006 44.297 --- 99.265

344 55.998 .147 .007 43.141 --- 99.293

345 57.067 .168 -.017 41.637 --- 98.855

346 57.834 .162 -.003 40.631 --- 98.624

347 59.383 .220 .007 39.498 --- 99.107

348 59.763 .174 .004 38.741 --- 98.681

349 61.193 .263 -.012 37.850 --- 99.294

350 60.820 .499 -.010 36.774 --- 98.083

351 62.245 .269 -.009 36.380 --- 98.885

352 62.695 .059 .002 35.104 --- 97.860

353 61.348 3.872 .012 33.015 --- 98.248

354 64.923 .270 -.008 34.661 --- 99.846

355 65.745 .363 -.029 34.140 --- 100.219

356 65.329 .336 .016 33.287 --- 98.968

357 66.446 .480 .000 32.807 --- 99.732

358 66.232 .437 -.009 32.246 --- 98.906

359 68.073 .282 .000 31.814 --- 100.169

360 67.658 .306 .013 31.365 --- 99.342

361 68.051 .358 .004 31.018 --- 99.431

362 68.374 .390 .013 30.217 --- 98.994

363 29.768 28.703 .018 14.383 --- 72.872

364 68.313 .380 -.003 30.694 --- 99.384

365 71.621 .462 .010 27.391 --- 99.484

366 71.649 .362 -.025 27.720 --- 99.706

367 71.290 .327 -.010 27.765 --- 99.372

368 71.315 .398 -.003 27.864 --- 99.575

369 71.726 .282 -.007 27.620 --- 99.621

370 72.036 .304 -.006 27.436 --- 99.770

371 72.546 .254 .008 26.966 --- 99.774

372 72.605 .206 .004 26.705 --- 99.519

373 73.202 .244 .014 26.185 --- 99.644

374 73.589 .216 -.010 25.956 --- 99.751

AVER: 49.089 1.389 -.002 48.090 --- 98.565

SDEV: 26.548 4.891 .011 26.706 --- 3.846

SERR: 3.832 .706 .002 3.855 ---

%RSD: 54.08 352.14 -597.27 55.53 ---

STDS: 526 506 541 523 ---

STKF: 1.0000 .9635 .9933 1.0000 ---

STCT: 11795.9 74090.3 15247.8 26182.7 ---

UNKF: .4792 .0050 .0000 .4958 ---

UNCT: 5768.6 398.1 -.2 13218.3 ---

UNBG: 32.2 41.4 18.5 55.1 ---

ZCOR: 1.0343 3.2420 1.1506 .9586 ---

KRAW: .4890 .0054 .0000 .5048 ---

PKBG: 169.93 5.72 .99 228.95 ---

INT%: ---- -.02 ---- ---- ---

TDI%: ---- 9.396 ---- ---- ---

DEV%: ---- .7 ---- ---- ---

TDIF: ---- LOG-LIN ---- ---- ---

TDIT: ---- 66.77 ---- ---- ---

TDII: ---- 384. ---- ---- ---

TDIL: ---- 5.95 ---- ---- ---

BLNK#: ---- 12 ---- ---- ---

BLNKL: ---- .000000 ---- ---- ---

BLNKV: ---- .933238 ---- ---- ---

Note also that I utilized the blank correction for carbon by analyzing some points on a portion of the sample that was uncoated pure iron. The analysis above shows a carbon blank of 0.933 wt%, which is then subtracted out during the matrix iteration in Probe for EPMA. Does this 0.9% represent the native hydrocarbon contamination layer on the sample? I don't know, but I also noticed that the carbon TDI plots are unusual but I'll post those in another post.