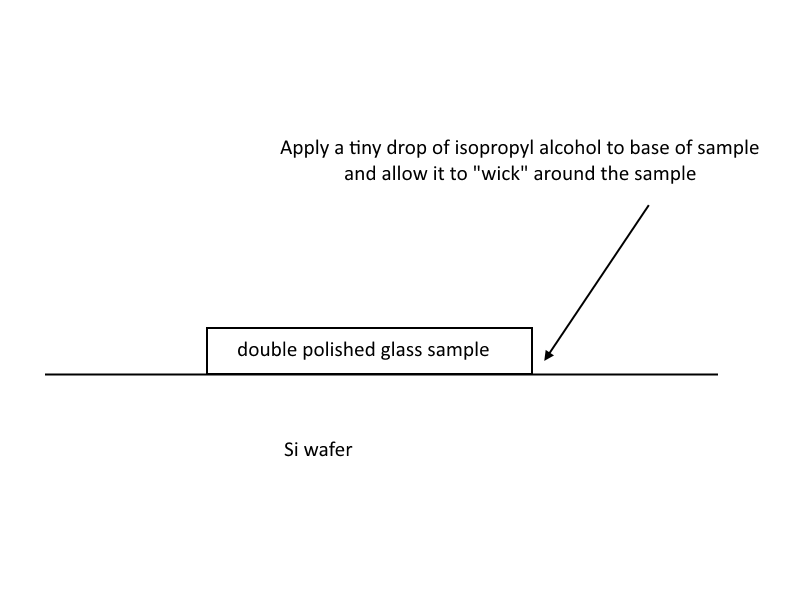

I posted this idea for using a tiny drop of isopropyl alcohol to adhere small flat samples to an Si substrate (or Al stub) a while back:

The idea being to allow the alcohol to "wick around" the edge and in dissolving hydrocarbon residues and then evaporating, such small flat samples will stick to a flat surface such as an Si substrate or Al stub without the need for gluing your samples using epoxy.

Previously we found that performing thin film analysis of multiple small cleaved pieces of Si weren't stable using just a 25mm carbon tab on an Al stub. The carbon tabs would move around and some pieces would go out of Bragg focus over time. Some relief can be had by utilizing the "hard" carbon tabs, but even better is the isopropyl "wick around" method.

The samples stay right where they are for the duration of the WDS measurement, and then when you want to re-use the Al stub, a tiny amount of pressure using a small needle is enough to dislodge the small pieces of Si wafer.

Recently I came across a company that could produce nice round pieces of Si wafer in various diameters including 25 mm, that can also be used in place of an Al stub. Here's a pic of a tray of 25 I bought that are cut to 25 mm so they'll fit right into my sample holder:

Then I adhere the small cleaved pieces of Si wafer to the large (25 mm) Si wafer each with a tiny drop of isopropyl (staying away from the edges), add a spacer ring equal to the thickness of the Si pieces, and then I'm automatically top referenced for analysis.

Just FYI.

Oh, I should mention that they cost about $200 for 25 wafers, but since they're totally re-usuable that seems like a good deal.