Hi all,

I'm not sure if this topic has been discussed elsewhere in the forum, but does anyone know if there has been any systematic study on the suitability of using NIST/NBS steel standards as microprobe standards, i.e. homogeneity of them at microscale? I understand the composition of most of the commercial available ones were based on bulk chemical analysis method. what is your experience with them?

Many thanks already.

Jeff

Hi Jeff,

There is nothing systematic about the data below, but I threw a couple of NIST alloy SRMs that I had already mounted into the instrument over the weekend and run a bunch of elements on both. The data looks pretty good but I wasn't able to run a second set of standards for a drift correction as the filament blew during the last traverse.

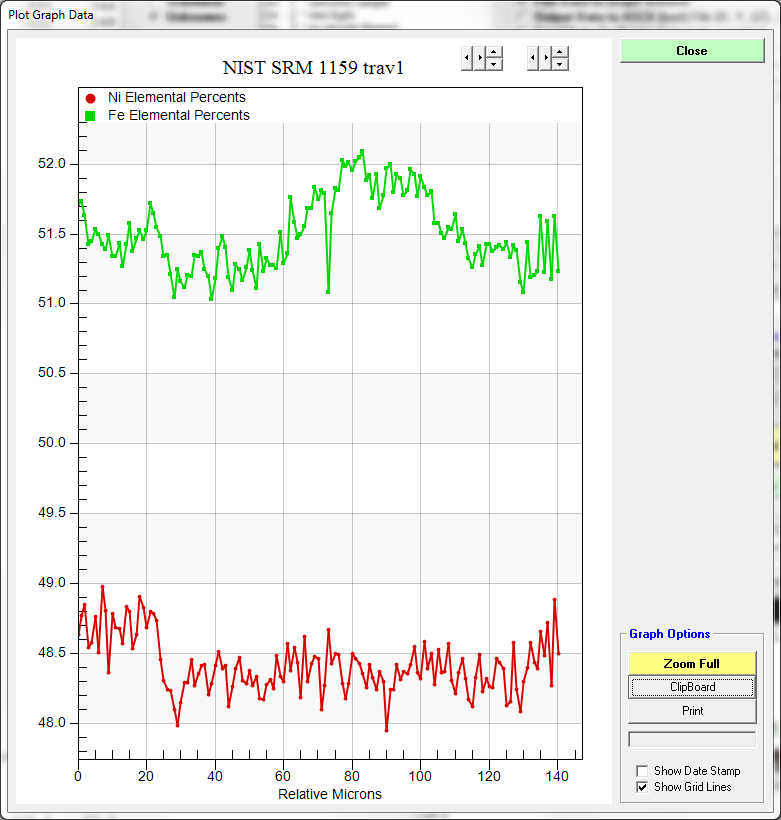

I suspect the answer to your question is going to be "it depends". That is it depends on which SRM standards we are talking about. Here is the the first one I ran which is a NiFe alloy, SRM 1159 to be exact. First the major elements:

Note that the Fe appears to vary a little, but according to the homogeneity range calculations below, the Fe is homogeneous within the 1% precision confidence interval. The minor and trace elements look like this:

Clearly the Cu is *not* homogeneous, but the others look pretty good.

Finally I turned on the Homogeneity Range calculations from the Calculation Options dialog in the PFE Analyze! window and we get this output:

Range of Homogeneity (t-test) in +/- Elemental Weight Percent (Average of Sample):

ELEM: Ni Mo Cr Fe W Co Si Mn V Cu O

60ci .013 .000 .000 .017 --- .000 .001 .001 .000 .008 .000

80ci .021 .000 .000 .026 --- .000 .001 .001 .000 .012 .001

90ci .026 .000 .000 .034 --- .000 .001 .001 .000 .016 .001

95ci .032 .000 .000 .040 --- .000 .001 .001 .000 .019 .001

99ci .042 .000 .000 .053 --- .000 .002 .002 .000 .025 .001

Test of Homogeneity (t-test) at 1.0 % Precision (Average of Sample):

ELEM: Ni Mo Cr Fe W Co Si Mn V Cu O

60ci yes yes yes yes --- yes yes yes yes no yes

80ci yes yes yes yes --- yes yes yes yes no yes

90ci yes yes yes yes --- yes yes yes yes no yes

95ci yes yes yes yes --- yes yes yes yes no yes

99ci yes no yes yes --- yes yes yes yes no yes

Level of Homogeneity (t-test) in +/- Percent (Average of Sample):

ELEM: Ni Mo Cr Fe W Co Si Mn V Cu O

60ci .0 .4 .2 .0 --- .1 .2 .2 .1 1.3 .2

80ci .0 .6 .4 .1 --- .2 .2 .2 .1 2.0 .3

90ci .1 .8 .5 .1 --- .2 .3 .3 .2 2.6 .4

95ci .1 .9 .6 .1 --- .3 .4 .4 .2 3.1 .4

99ci .1 1.2 .8 .1 --- .4 .5 .5 .3 4.0 .6

Range of Ideal Homogeneity (t-test) in +/- Elemental Weight Percent (Average of Sample) (Meisenkothen and Donovan):

ELEM: Ni Mo Cr Fe W Co Si Mn V Cu O

60ci .095 .000 .002 .050 --- .000 .006 .006 .000 .004 .001

80ci .145 .001 .003 .077 --- .000 .009 .010 .000 .007 .002

90ci .187 .001 .004 .099 --- .001 .011 .012 .000 .009 .003

95ci .223 .001 .005 .118 --- .001 .013 .015 .000 .010 .003

99ci .294 .001 .006 .155 --- .001 .018 .020 .000 .014 .005

Range of Actual Homogeneity (t-test) in +/- Elemental Weight Percent (Average of Sample) (Meisenkothen and Donovan):

ELEM: Ni Mo Cr Fe W Co Si Mn V Cu O

60ci .160 .000 .002 .205 --- .000 .006 .007 .000 .097 .005

80ci .244 .001 .003 .313 --- .001 .010 .010 .000 .148 .008

90ci .313 .001 .004 .402 --- .001 .012 .013 .000 .190 .010

95ci .374 .001 .004 .480 --- .001 .015 .016 .000 .227 .012

99ci .494 .002 .006 .635 --- .001 .020 .021 .000 .300 .016

Next I will look at SRM C2402, which is a very different story!