One of the interesting aspects to Probe for EPMA is that one can calculate the same data in multiple ways, for example, one can acquire data using off-peak backgrounds and calculate the quant results using the off-peak background method.

But one can also take that same data (usually one should first copy the MDB file to another folder just to keep things straight), and then proceed to apply MAN backgrounds to those same measurements by simply ignoring the off-peak intensities as described here:

https://probesoftware.com/smf/index.php?topic=4.msg2255#msg2255https://probesoftware.com/smf/index.php?topic=987.msg6455#msg6455One will find that one can attain about 40% better precision than off-peak backgrounds (in 1/2 the acquisition time!) as explained in our 2016 paper (Donovan et al., 2016, Amer. Min.) and also improve accuracy by utilizing a blank correction.

However, one can also calculate the same data using different ways of specifying unanalyzed elements as well. For example one could specify a fixed concentration of an element, or one could specify to calculate an unanalyzed element (or formula) by difference.

Recently Anette von der Handt measured oxygen for some materials using quantitative x-ray mapping and wanted to compare the measured (and calculated excess oxygen) using measured oxygen, with the Droop et al. method for calculating excess oxygen from ferric iron based on charge balance and a mineral formula. I'll post on using the ferric/ferrous method in CalcImage in the CalcImage board in a moment, but let's start with the Droop method for calculating excess oxygen in Probe for EPMA first, because I had to remember how this needs to be done, when oxygen is measured.

So, we've measured oxygen and now we have a result in say a magnetite material:

And we're within ~1.3% relative so not too bad (of course using empirical MACs from Pouchou and Bastin!). But now we want to see how this direct measurement result compares to simply calculating our excess oxygen from ferric iron, because, well you know, we had to give up a spectrometer just to measure oxygen! And maybe using the Droop charge balance method we can do just as well, at least maybe for excess oxygen in magnetites...

So we go (after making a copy of our MDB file!) into the Calculation Options dialog in Probe for EPMA and select the Ferrous/Ferric method for our magnetite material and specify oxygen by stoichiometry, and then we get this error:

Doh! If we try and quantify with both measured oxygen *and* oxygen calculated by stoichiometry, we will be adding oxygen *twice* into the matrix correction, and that's no good, right?

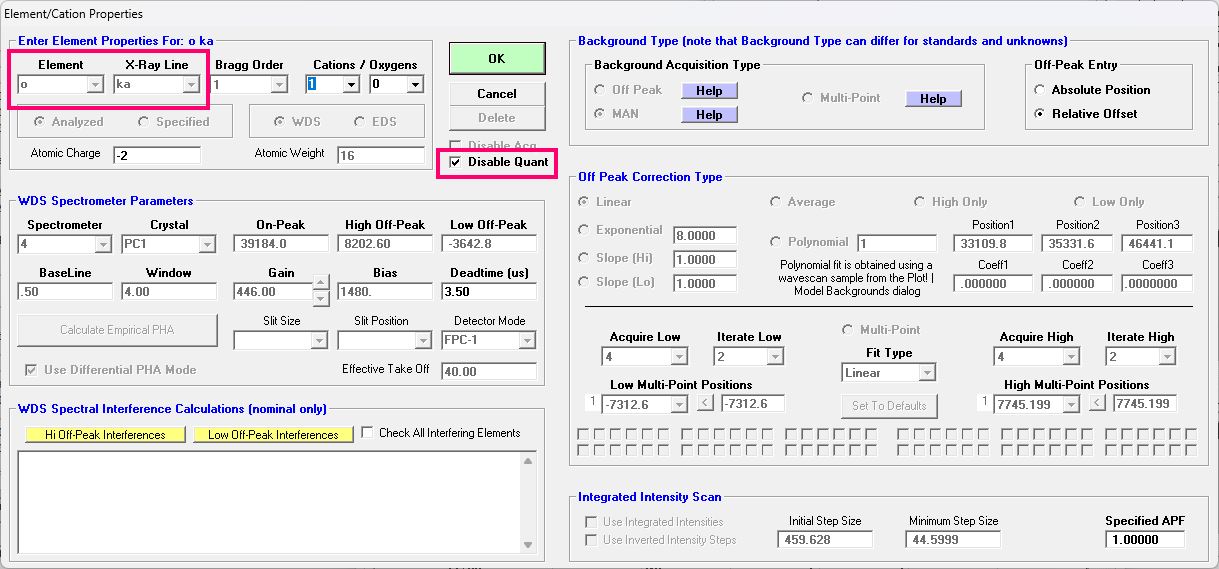

OK, so what do we do? Well, we need to disable the measured oxygen for quantification from the Elements/Cations dialog as seen here:

And now we can go back into Calculation Options and specify our ferric/ferrous formula and oxygen by stoicihiometry. Now when we quantify our magnetite material we obtain this result:

Wait, what the heck? We've got our excess oxygen from ferric iron calculated properly (6.88 wt%) but our totals are low by exactly that amount! And that's because although the excess oxygen from ferric iron was calculated and included into the matrix correction, it was not output to the user! And that's because there's no place to print it out since the only oxygen column present is the measured oxygen column which is reserved for the measurement results and we disabled the measured oxygen for quantification.

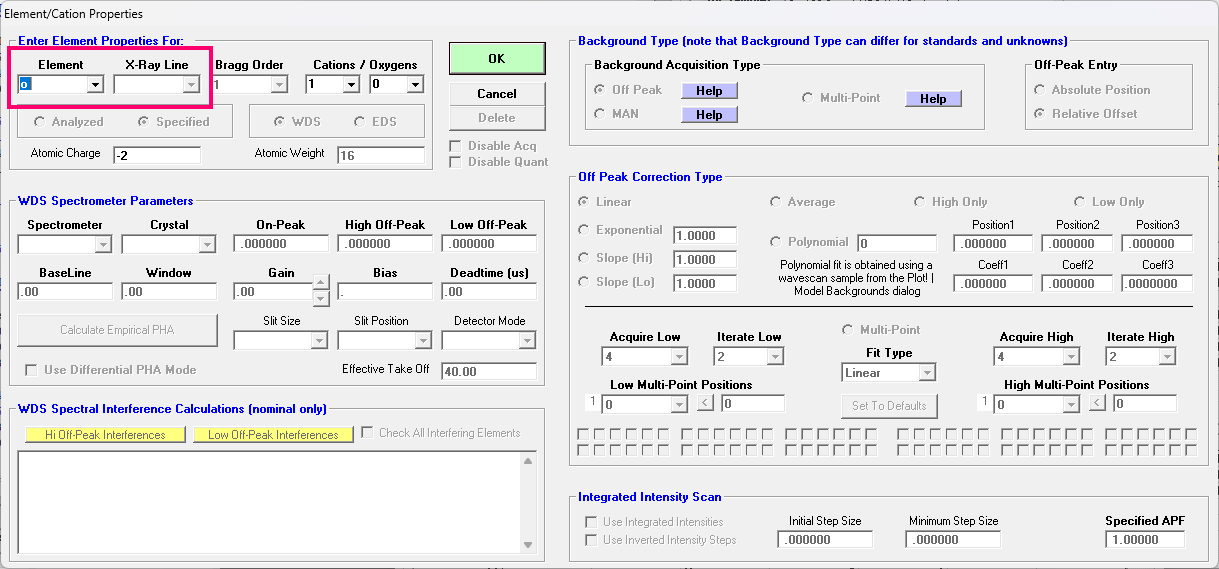

So what we need to do is, add oxygen as an *unanalyzed* element to our element list as seen here:

Remember, an unanalyzed element is simply an element *without* an x-ray line specified. Now let's calculate the concentrations again:

Well now, that's pretty neat, isn't it?

But it took me a minute to remember all this when looking at Anette's x-ray maps in CalcImage, where she basically wanted to do the same thing but for maps! I'll post more about that in a bit in the CalcImage topic...